As the domestic E-BIKE market is heating up, more and more E-BIKE products are springing up. Unlike the transparency of traditional bicycle products, riders' knowledge of E-BIKE products is still in its infancy, and the quality of E-BIKE products on the market varies, how to avoid stepping on the pit? Today we will talk to you about E-BIKE things.

The working principle of electric power system

No matter what brand of electric power system, the essence is to convert electrical energy into kinetic energy and apply it to the transmission system of the bike, so that riding becomes easier and less laborious. And we often say E-BIKE motor, essentially contains the motor (electrical energy into kinetic energy) and the deceleration system (kinetic energy to the bike) two parts.

When the system works, the motor outputs power at a high speed and low torque, and then through a deceleration system, amplifies the torque while allowing the output speed to be close to the pedaling frequency of the human leg (mid-motor) or the speed of the wheelset (hub motor). If the motor does not go through the speed reduction directly to the tooth plate, the output torque of the motor is not enough to drive a couple of hundred pounds of human-vehicle complex, and the second is that neither the legs of the rider can withstand the pedaling frequency of thousands of revolutions.

Mid-mounted, hub that strong?

The current market can be broadly divided into two types of booster motor systems: mid-mounted and hub type. Mid-mounted motor refers to E-BIKE's drive motor installed in the frame five-way position of the motor (divided into frame integrated type and five-way external type), the motor is connected to the body and connected to the rear wheel through the chain to transmit power. Hub motor refers to the E-BIKE drive motor installed in the hub position of the car, the motor acts directly on the wheelset, the kinetic energy does not need to be transmitted through the chain.

For sports models, the integrated mid-motor is undoubtedly the best choice, first of all, the motor drive system is located in the frame five-way, will not break the weight balance of the whole car, and for full shock models, mid-motor compared to the rear hub motor, reducing the underspring mass, the rear shock feedback is therefore more natural, there are inherent advantages in off-road handling. Secondly, the wheelset is relatively easy to replace, if it is a hub motor, the enthusiast to upgrade the wheelset is almost an impossible thing, because in addition to the parameters of the wheel itself, there are various parameters of the configuration motor, it is difficult for ordinary consumers to have the conditions to do, while the mid-mounted motor does not exist in this case, you can buy the frame set DIY, greatly increasing the playability. Third, in off-road riding, the impact of the mid-mounted motor compared to the hub motor is smaller, so it is more favorable in terms of protection, thus reducing the risk of damage to the motor and reducing the failure rate.

For non-sports models, the choice of hub motor does not require a major change to the traditional frame structure, coupled with the low cost, easier for commuters to accept the class.

The motor is divided into internal and external, do you know? Inner rotor motor, outer rotor motor

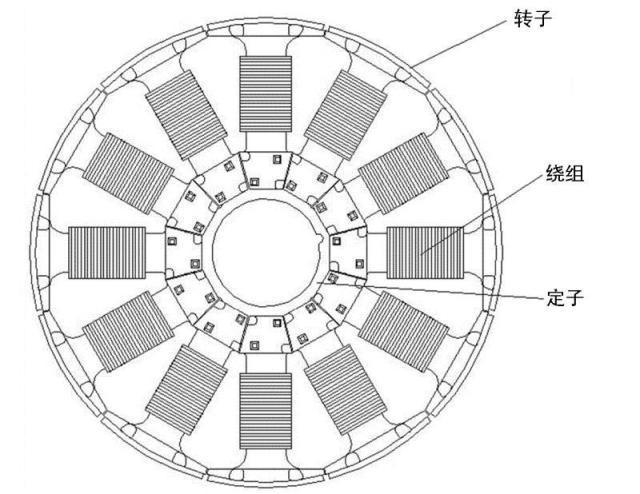

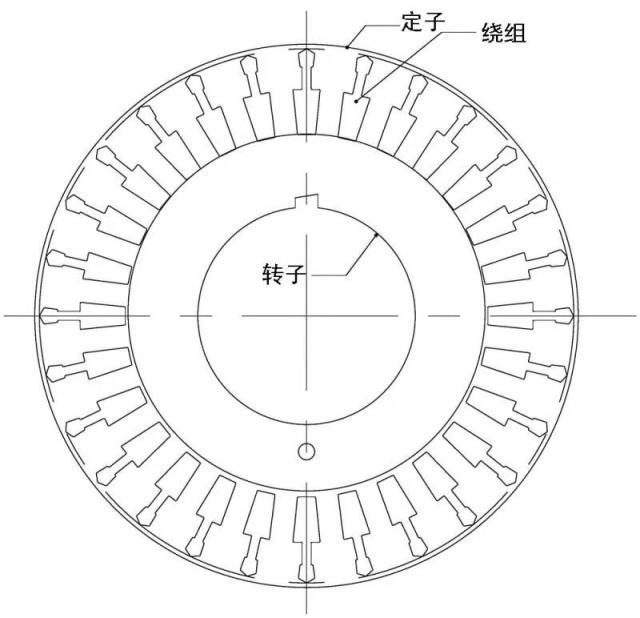

Here first introduced a concept: rotor and stator. Simply put, in the motor power system, the fixed part is called the stator, the rotating part is called the rotor, the motor will convert electrical energy into kinetic energy, so that the rotor rotates, the rotor is connected to the gear to drive the entire power system.

After introducing the rotor and stator, then the inner and outer rotor is easy to understand. As the name suggests, the inner rotor motor is a motor with the stator in the outer ring and the rotor rotating in the inner ring, while the outer rotor motor is a motor with the stator fixed in the inner ring and the rotor rotating in the outer ring.

In the case of the same rotor weight, the inner rotor does not have the same rotational inertia as the outer rotor, so the kv of the inner rotor motor is high and the torque is low, while the outer rotor motor is just the opposite. There is no absolute sense of superiority or inferiority between the two. Relatively speaking, the inner rotor motor has small torque and high speed, which is often used in small aircraft and car and boat models; while the outer rotor motor has good heat dissipation and strong load capacity, and for E-BIKE, the space in the inner ring of the outer rotor motor stator can be used to place multi-stage speed reduction devices, thus reducing the overall volume of the electric power system.

Coaxial motor, parallel shaft motor

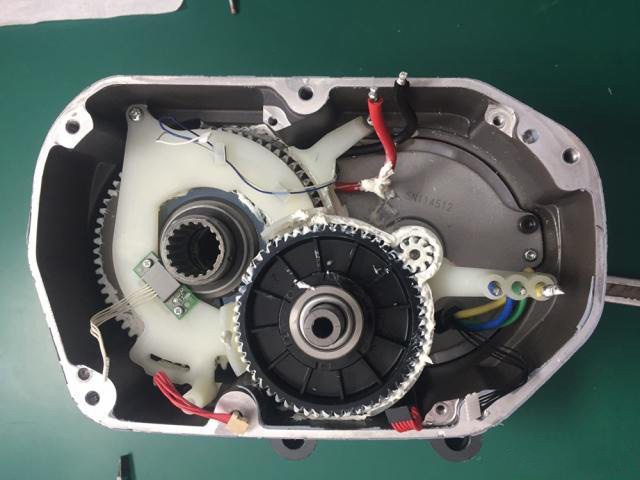

As mentioned above, the motor converts electrical energy into kinetic energy and does not apply it directly to the tooth plate, but through a series of speed reduction devices to amplify the torque and reduce the speed of the final transmission to the tooth plate, therefore, the motor power output shaft of E-BIKE and the tooth plate shaft of the bicycle are structurally two shafts, connected by a speed reduction device in the middle, and we can classify the E-BIKE mid-motor as coaxial motor according to the difference of the relative positions of these two shafts. BIKE mid motor can be divided into coaxial motor (also called concentric shaft motor) and parallel shaft motor.

The picture shows the transmission structure of Shimano mid-motor, which is also the motor used by our company. The white pinion on the right side is connected to the power output shaft of the motor, while the leftmost one is connected to the tooth plate shaft, the two axes are in parallel position, and the middle is connected by a series of transmission gears, so the motor of this structure is called parallel shaft motor.

Coaxial motor, as the name implies, means that the tooth plate shaft and the power output shaft of the motor are on the same axis. These motors are mostly external rotor motors, using the inner ring of the motor stator and the space on both sides to place the reduction system, so the appearance of the coaxial motor looks smaller and the internal structure is more compact. However, in the limited space, it is not easy to realize multi-stage reduction, and at the same time to take into account the torque, heat dissipation and ensure the concentricity of the drive shaft. The TTIUM coaxial mid-motor booster system developed by TTIUM over two years has successfully broken through foreign technical barriers, with three world patent technologies, twenty-one national patent technologies and lifetime unique number, and its performance has reached the international advanced level.

What is the meaning of the size of the tooth plate?

Often concerned about electric power products enthusiasts may notice that the same mid-motor E-BIKE, some discs are large, some discs are small, this is why?

The mystery is that there is a 2.4 times speed-up device inside the motor where the crank is connected, that is, when the crank is pedaled one turn, the disc rotates 2.4 turns, so the small disc of 16T is equivalent to the pedaling effect of 39T discs. Moreover, the speed up device is purely mechanical, even if there is no power, it does not affect the pedaling at all, and does not produce additional resistance.

Use the speed to compensate for the torque, on the one hand, can reduce the chain tension burden, which is especially important for the violent output of E-BIKE. On the other hand, the high rotational speed of the tooth shaft reduces the pressure of the motor reduction mechanism in the limited space. The size of the reduction mechanism, the running burden, and the overall size and weight of the motor will all be reduced.

The biggest difference between E-BIKE and electric donkey is that E-BIKE can sense the rider's riding status so as to give proper assistance, and the role of the sensor is to collect the movement data of people and cars, whether the sensor is reliable, directly determines whether an E-BIKE is really intelligent or blind assistance.

The sensors currently used in E-BIKE can be divided into torque sensor, pedal frequency sensor and speed sensor. Torque sensors are used to measure the slight deformation of the metal surface after pedaling to obtain a high precision torque value. According to the position of the torque sensor measurement, it can be subdivided into rear axle hook and claw sensor, middle axle sensor, disc claw sensor.

The pedaling frequency sensor, as the name implies, measures the pedaling frequency to determine the main demand, the faster the pedaling frequency, the harder the boost, the slower the pedaling frequency, the weaker the boost. Speed sensor is the same, but such a setting obviously can not match the real needs, for example, in climbing or encountering headwinds, the pedaling frequency and speed of people become slower, while the motor default riders do not need too much assistance. Therefore, the use of pedaling frequency / speed sensor E-BIKE usually join the pure electric mode, however, this to a certain extent also deviates from the original purpose of electric power. Some brands also call it a speed sensor or magnetic ring sensor in order to hide the eyes and ears to improve the style. And a reliable E-BIKE pass often use torque, pedaling frequency, speed sensor superimposed, through the integrated operation to determine the current riding status.

I believe the introduction of so much, whether senior riders or amateur white should have some understanding of ebike, choose us trustworthy!